Concept introduction

FORCE provides the scientific community with large machines that can simulate conditions that are otherwise inaccessible to humans. Here we will explore some concepts that often come up when discussing high pressure research.

Do you have a question about something not covered here? Contact us on Bluesky or X @FORCEhighP or via the contact form in the main menu.

About high pressure

Force distribution

Compressive force (pressure) is generated in the multi-anvil press and high pressure torsion press by a hydraulic jack. The internally-heated pressure vessel uses inert argon gas to apply pressure to a sample. Pressure is calculated as force divided by area (P = F/A). This means that as area increases, pressure decreases. High pressure experiments have been limited by this relationship – in order to reach an extremely high pressure with the same amount of force, the area of the sample material must decrease. Unfortunately, the amount of sample material required to reach extremely high pressures is too small for many practical uses. The new, larger multi-anvil that is a part of FORCE (Ichiban), can exert more force than a conventional multi-anvil. More force allows for a larger sample area at the same pressure, which in turn means a larger sample size. Or, we can use the same size sample but take it to a much higher pressure during the experiment.

Crystal structure

To high pressure scientists, “crystal” doesn’t only refer to types of minerals like quartz or ruby, but refers specifically to a solid material whose atoms are arranged in a highly ordered, periodically repeating arrangement. This arrangement of atoms is the main reason for a material’s appearance and properties. For example, quartz and coesite are both composed of SiO₂, or silicon dioxide. Even though they are made of the exact same elements, the difference in crystal structure (hexagonal for quartz and monoclinic for coesite) leads to different properties, such as changes in density and hardness. High pressure experiments are a way to change the crystal structure of a given material.

Phase transitions

In the realm of high pressure, “phase transition” doesn’t mean changing from a solid to a liquid or a liquid to a gas. Instead, when high pressure scientists talk about “phase transitions”, they usually mean that the atoms within a solid substance are moving around and taking on a new configuration, but remaining solid! At high enough pressures and temperatures, these atoms will often rearrange so much that their crystal structure is changed. Many high pressure scientists are interested in phase transitions because they can allow a familiar material to take on new and interesting (and useful!) properties.

Material characterization

Rearranging crystal structures and discovering new materials is interesting (and potentially innovative). But, we need to know details about those materials to figure out how to make them useful in our daily lives. This is where “material characterization” comes into play. The field of material characterization uses a variety of methods (from X-rays to electron beams) in order to find not only the microstructure of a material, but also its composition and properties. These types of analyses, which Arizona State University is known for as a world-renowned research facility for electron microscopy, are how the findings from experiments conducted in FORCE are understood and the first step to putting them to use.

Multi-anvil concepts

Our machines “Ichiban” and “Jasmine” are examples of two types of multi-anvil press (or just “multi-anvil” or “MA). Here we will explore some of the important concepts having to do with the multi-anvil.

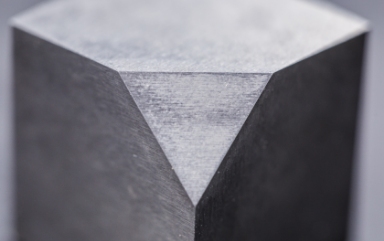

Anvils

First-stage anvils (pictured above) are one of the most important parts that distribute force within a multi-anvil. Generally, these anvils are made out of tungsten carbide. Second-stage anvils are made out of either tungsten carbide or sintered diamond, with the tungsten carbide anvils being used for lower-pressure applications and the sintered diamond anvils exclusively used for extremely high-pressure experiments. The second-stage anvils fit in the cubic cavity inside the first-stage anvils. The second-stage anvils are cubes of the given material, truncated on each corner to both create a surface for the pressure medium — an octahedron that contains the actual experimental sample — to sit, and to remove points where pressure gathers. These anvils have spacers between them to prevent any contact being made between anvils, both to help with pressure distribution and anvil lifetime.

Principle of massive support

Many high pressure devices that use anvils (which are usually cubes of tungsten carbide or sintered diamond) tend to utilize the principle of “massive support.” In essence, this is a design principle that allows the massive stresses experienced by those anvils to disperse without breaking the anvils, allowing them to reach loads that would otherwise shatter them.

Kawai-type apparatus

A Kawai-type high-pressure apparatus is the type of multi-anvil press used in many high-pressure devices, including FORCE’s Ichiban. The first-stage anvils apply force to the second-stage anvils. Nestled within the 8 second-stage anvils is an octahedral pressure medium that contains the experimental assembly. The assembly is composed out of a material that can handle high pressure (such as magnesium oxide) and contains the experimental sample and any heating elements. To set up an experiment, 8 second-stage anvil cubes are assembled around the octahedron (4 cubes on the bottom, octahedron in the middle, and 4 cubes on top). The resulting arrangement looks like a larger cube. This is placed into the first-stage anvils, which are attached to the multi-anvil. There are 3 first-stage anvils on the top and bottom of the multi-anvil press — 6 total for equal contact with the cubic second-stage anvil arrangement. When pressure is exerted on the first-stage anvils, it is evenly distributed to the second-stage anvils and then to the sample in the middle. The Walker-type multi-anvil shown above is a special kind of Kawai-type multi-anvil that uses removable first-stage anvils that look like wedges. Ichiban is a split-column multi-anvil, which means its first-stage anvils are permanently attached to upper and lower parts of the apparatus.